Medical

Medical Applications

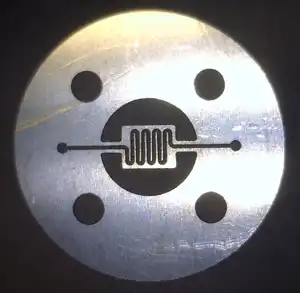

The part pictured is one of many parts microwaterjet® has cut for use in the medical field. The microwaterjet® process was chosen over other technologies because:

- Kerf requirement for this part was smaller than that of conventional water jet technology;

- Microwaterjet® for prototype quantities was less expensive than wire EDM;

- Laser cutting would be difficult due to the thin wall segments in the interior feature.

The part is made out of Stainless Steel and is 0.984” x 0.039” (25mm x 1 mm) with the thinnest geometry being 0.008” (0.2mm). The aspect ratio of the fine features is 1:5. This is the 0.2 mm wide feature with a 1 mm thickness.

Click HERE for more information

Contact Us

"*" indicates required fields