5-Step Microwaterjet® Project Process

How it Works

Get Your Custom Solution

Call 704-948-1223 or Schedule A Free Consultation

"*" indicates required fields

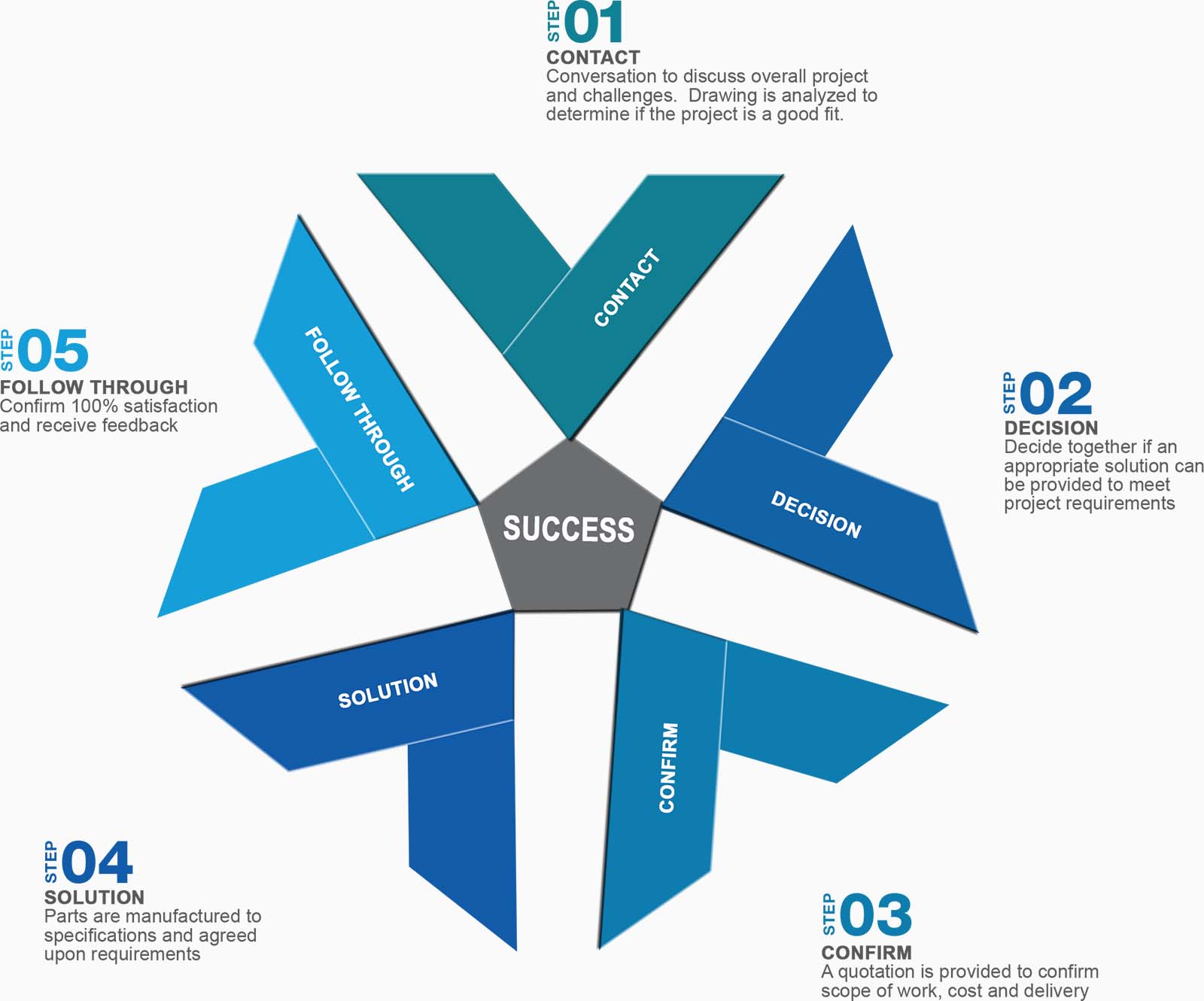

Our Proven 5-Step Path to Microwaterjet® Success

When tolerances shrink to microns and deadlines can’t slip, process matters as much as technology. At Meyer Tool Huntersville we pair our proprietary Microwaterjet® equipment with a disciplined, five-step partnership model that takes you from first conversation to flawless parts—and circles back for continuous improvement. Below you’ll see exactly what to expect at every stage.

Step 1: Contact – Let’s Talk Possibilities

Objective: Understand your goals, challenges, and drawings.

We begin with a candid conversation—phone, video, or onsite—to review your application, tolerances, and material constraints. Our technical team analyzes your requirements to be sure Microwaterjet® is the best fit (and helps you decide if it’s not).

Typical outcomes:

- Clarified performance targets

- Identification of any design-for-manufacturability tweaks

- NDA execution if required

Step 2: Decision – Green-Lighting the Right Solution Together

Once the data are in, we sit down—as partners—to decide whether we can meet or exceed your specs. If we can’t, we’ll tell you early. If we can, you’ll know exactly how and why Microwaterjet® wins versus laser, wire EDM, or chemical etching.

Key evaluation points:

- Material suitability (metals, composites, ceramics, exotics)

- Feature size vs. 0.2 mm kerf width capability

- Required geometric tolerance of ±0.01 mm

- Surface finish targets (up to N7 / Ra1.6 µm)

Step 3: Confirm – Scope, Cost & Delivery in Writing

Clarity drives speed. We issue a formal quotation that locks down:

- Scope of work: part count, material, finish.

- Timeline: prototyping and production schedules.

- Investment: transparent, line-item pricing.

Only after you sign off do we release your job to the floor—eliminating surprises later.

Step 4: Solution – Precision Manufacturing in Action

Your parts move through our ISO 9001-certified facility where quality control ensures your part will be made to your specifications. The same expert who approved your drawing supervise cut quality, ensuring:

- Positioning accuracy: ±0.003 mm

- Heat-free process: zero HAZ, no recast layer

- No secondary ops: parts meet spec right off the table

Need rapid prototypes? We can cut single pieces up to production volumes.

Step 5: Follow-Through – 100 % Satisfaction, Documented

Delivery day is not the finish line. We confirm receipt, review your scope of work, and collect feedback to refine future runs. If anything isn’t perfect, we correct it—fast.

What follow-through looks like:

- First Article Inspection and in process inspection reports when required

- Debrief call to capture lessons learned

- Recommendations for next iteration

Success: A Repeatable Advantage

Because each project flows through the same rigor-tested steps, you enjoy shorter lead times, lower total cost, and peace of mind that every detail is important. That’s how Meyer Tool Huntersville turns complex requirements into repeatable wins.

Trust the 5-Step Process—Start Yours Today

Ready to prototype or scale production? Upload your drawing or call 704-948-1223 to speak directly with a Microwaterjet® technical staff.