Waterjet Cutting vs. Wire EDM Cutting

There have been many advances in wire EDM cutting technology over the years. But even with automated threading, higher velocity crushing and more, the basic rules have never changed. Processed material must be conductive, and the material removal process must still be thermal. Let’s review what your options are when choosing between wire EDM cutting and Micro waterjet® cutting.

Advantages of Wire EDM Cutting

Accurate Process

Wire EDM is capable of reaching dimensional tolerances as good as one micron.

“Stack” Cutting For Parts

One advantage of wire EDM cutting is its strength for cutting thick materials. This also makes it capable of cutting many thin materials stacked on top of one another.

No Burr on Cut Edge

Since wire EDM does not mechanically remove materials, there’s no burr left along the cut edge. Additionally, wire EDM cutting is ideal for creating tapered parts, such as extrusion molds.

Surface Finishing

Along with cutting accuracy, the surface finish of wire EDM can be mirror-like, down to a 0.1 micron Ra finish.

Disadvantages of Wire EDM Cutting

Slow Cutting Process

Many manufacturers who utilize wire EDM technology run numerous systems in a “cell”. This is due to the lack of speed this process offers. During some speed comparisons conducted by one of our customers, the average linear speed of cutting was just under 2mm/min. This is about 20-30x slower than Microwaterjet® cutting.

Leaves Heat Affected Zones

Since electrical discharge machining is a thermal process, there is always some heat affect on the cut edge surface. In some cases, this has to be dealt with during post-processing.

Can’t Cut Non-Conductive Materials

Wire EDM processing can only be accomplished while machining electrically conductive conductive material.

Expensive Prototype Production

On projects that require numerous design modifications during the prototype stages, wire EDM processing is not always a good fit due to the expense and time required to deliver parts.

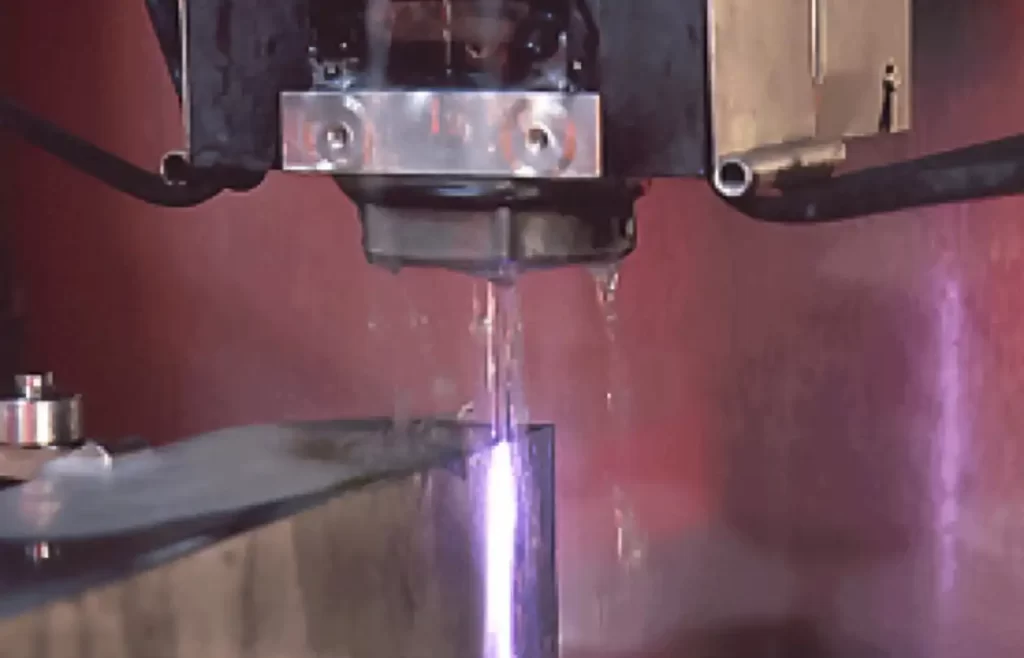

How the Microwaterjet® Excels Over Laser-Cutting

The Microwaterjet® process provides some key advantages that make it the more efficient choice over Wire EDM cutting for your parts.

Faster Cutting Process

Depending on material thickness, kerf requirement and geometric tolerance, the Microwaterjet® process can cut 20x-30x faster than wire EDM.

No Heat-Affected Zones

Since the Microwaterjet® uses a mechanical means of material removal, there is not enough heat generated to affect the material along the cut edge. Little to no post processing is required in this case.

Capable of Cutting Nearly Any Material

Due to the mechanical means of cutting, the Microwaterjet® process can cut a wide range of materials including high-tech alloys, noble metals and developmental compounds.

Affordable Prototype Production

Due to the cutting speed and capability to cut small batch prototypes to large volume production, the Microwaterjet® process can deliver your parts to you quickly, accurately and affordably.

See Why the Microwaterjet® Makes the Cut

Want to learn more about what the Microwaterjet® process has to offer? Contact Meyer Tool Huntersville today to get started with helping you find the cutting solution that meets your product requirements.