Waterjet Cutting Benefits

Our High-Precision Advantage

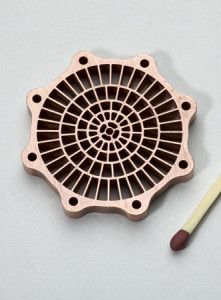

Our Microwaterjet® was specifically designed to machine two-dimensional, high-precision micro parts. Our Microwaterjet® offers multiple advantages that show why our customers choose us over our competitors:

Fast Delivery Time

Our immediate response time and increased machine capacity enables us to offer expedited orders for shorter lead times. The Meyer Tool Huntersville production team maintains a flexible schedule, allowing for overlapping and extended shifts for rush orders.

Elite Research & Development Support

At Meyer Tool Huntersville, our client relationships strengthen our ability to provide optimal waterjet solutions.

At Meyer Tool Huntersville, our client relationships strengthen our ability to provide optimal waterjet solutions.

Our equipment and waterjet capabilities enable us to provide reverse engineering for research and development projects, and the production environment to support all levels of production solutions.

Cold Cutting Process

Other companies use wire EDM cutting and laser cutting, which are both thermal processes that use heat to remove the material. However, this can change the material’s state.

Our Microwaterjet® process uses mechanical means of material removal, which does not introduce the heat effect that thermal processes will create. Unlike EDM and laser cutting, our Microwaterjet® process cuts without Heat Affected Zones (HAZ). Therefore, we cut materials with little to no biocompatibility issues or a requirement for deburring.

From client testimonials, we’ve proven that mechanical energy is the best strategy to avoid this problem.

Wide Range of Materials

Our Microwaterjet® can cut a wide range of materials, from steel alloy to foam rubber.

Thermal and chemical material removal processes all have a very limited list of compatible materials. You can design your product with the best suited materials and rely on us to provide the precision you require to manufacture your parts.

Accuracy and Repeatability

Using glass scales and precision ball screw positioning systems, our Microwaterjet® cutting process offers more precision than conventional waterjets.

This gives you flexibility in your final product or desired finish. We can cut the smallest features in your design with customized quality finishes based on your requirements.

Precise Results

Our process offers a substantially smaller kerf width (0.08mm for pure water cutting, 0.2mm for abrasive cutting) compared to traditional waterjet machines (0.8 mm) that are primarily used to cut rough large shapes and/or thicker materials.

This allows for a 10-fold reduction in the jet cutting diameter, resulting in much finer accuracy from the very first production run. Our Microwaterjet® process produces more accurate results due to a positioning accuracy of +/-0.003mm.

Pristine Cleanliness

The industries we serve require a level of quality and cleanliness that we are familiar with. We take pride in every part that we produce and take ownership in the entire process. Whether your parts are aluminum or rare precious metals, our experts properly care for our customers’ products.

Complete our contact form to learn more about how our Microwaterjet® could help you discover a solution to your precision cutting needs.